Guided mill tour

On our mill tours, a guide will tell you the history of the three mills and show their working processes. The guided tour lasts almost an hour. It includes the unique building and working tools of the paper mill, the two centuries-old structures of the treadmill and the valuable industrial equipments of the water mill.

The mill tours are tailored to the needs of our visitors, so they are a real experience for adults and children, and can be combined with our activities.

Good to know! Access to the interior of the mills is only possible with guided tours. Individual visitors and families do not need to book in advance.

Guided Mill tours:

They start at guaranteed times, even for a single visitor.

ENTRANCE FEE:

Tickets can be purchased at the mill yard before the tours start.

Check in:

E-mail: muzeum@orfuimalmok.hu

Telephone: +3620/319 65 86

The Orfűi Malmok

Water mill

Dry mill

Paper mill

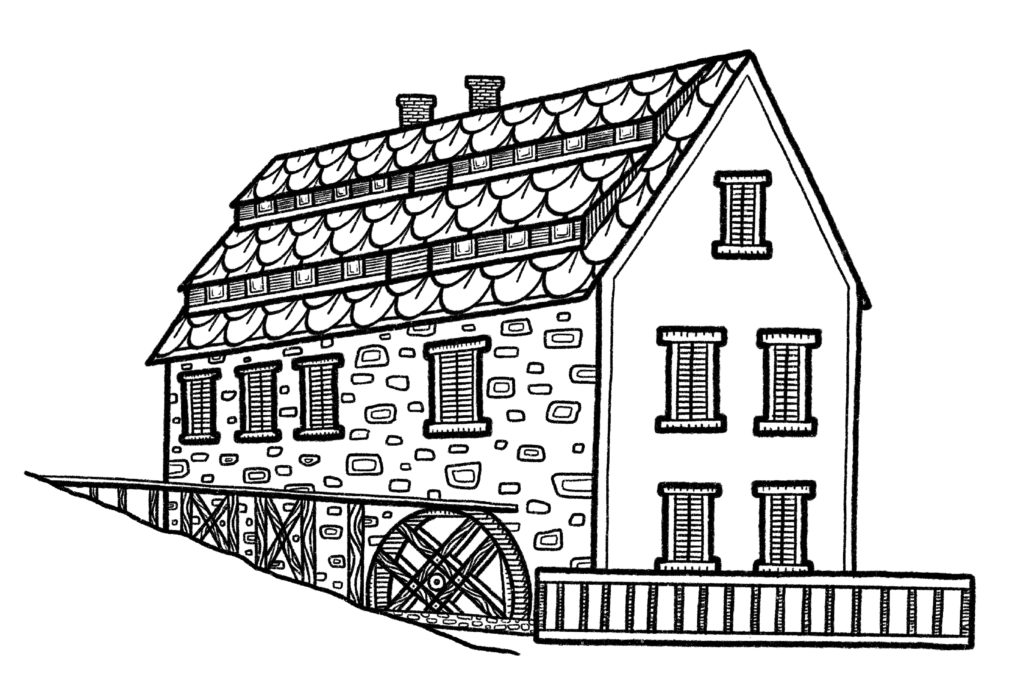

Water mill

The water mill’s patinated roller mills are a real historical curiosity, still perfectly suited for grinding grain. Visitors can still see the old technology in its original form. A guide will explain the process of grinding, grain transport, cleaning and sorting methods of the time. Visitors are able to touch the machines and see the system that makes the whole mill work up close in the wheelhouse.

The Hungarian milling technology of the industrial age was a world-class invention, and its essence were the rollers. The whole world admired the perfection of the latter – cunstructed by Hungarian mechanical engineer András Mechwart, (the founder of the Hungarian electrical industry). At the heart of the Orfű water mill is a magnificent and functional example of this technology, one of the last, remaining intact. The roller mill was used to grind cereals into flour. Grinding on rollers was a new technology following the use of millstones, However, even today, grinding with stones has its own place and role in the universe of mills.

Deprived of its original function, the mill, which was converted into a museum in 1970, was taken into the care of Antal Füzes (miller) and Péter Füzes (mill engineer) in 1993. In their capable hands, the machines were brought back to life for two decades, – the mill was running again until 2009.

There are no longer members of our team who would have chosen to become millers, but the responsibility and respect for the water mill is a tradition that is passed on through generations. As well as preserving the mill’s heritage, it is our mission to give a tribute to the former mill that served so many people for so many decades.

Dry mill

In Hungary, only four dry mills preserve this technology of grinding, which was dominant until the mid-19th century, and their heyday came to an end with the advent of steam mills. In Orfű, the heart of the machine, which is now in its retirement years, is a huge horse-powered wheel that transmits the driving force to the millstones via 400 teeth. The grain was ground between stones cut from red sandstone and then sorted using the first automated sieve in the milling industry: the grit sieve.

The old millers were the ‘engineers of the countryside’. Where need and demand dictated, they applied unique and sophisticated solutions to make their busunesses more effective. The mill of Mekényes (which now is known as the dry mill in Orfű) had an oil press as well. When the miller was not grinding flour, he could use his wheel-driven grinder to prepare the oilseeds for pressing. The pressing took place between two huge beams, each weighing one and a half tonnes and measuring six metres in length.

The handwheels of the wheelbarrow and the oil press can be turned by the brave and strong, but if they can’t, don’t fret! The centuries-old hand mills on display here are for everyone to try!

But beware! When entering the tiny door of the dry mill, there are always some who bang their heads against the door frame!

Paper mill

Paper and papermaking originates in ancient China. This closely guarded knowledge slowly spread to other parts of the world. In Europe, it only appeared at the end of the first millennium, arrived through the Arabic culture, and the first Hungarian paper mill was built 1512. The spread of paper-making in Mecsek began in the mid-18th century, after the end of the Ottoman rule. The first paper mills in Baranya were founded by the Bishop of Pécs, György Klimó. By the end of the 19th century, nearly 200 paper mills had been established in Hungary, but none of them has survived in its original form. The paper mill in Orfű was built in 2016 following the models of the former paper mills in Mecsek.

The traditional process of the “white art” is demonstrated in our mill using authentic but newly made equipments. Today, paper is still made here in the same way as it was centuries ago. The paper mill is a place of constant production process, thus we use modern machinery as well – to ensure high quality.

In the Orfű paper mill, the water wheel, like in the mills of the period, sets heavy hammers in motion, which produce the pulp for paper moulding with a great noise. In paper mills powered by steam – and later electric powered mills, the manual process had already become a rarity by the mid-19th century.

In our papermaking workshop, visitors can see the steps of the process, and after appointment, they can make their own paper in a series of workshops.

Contact us!

More information and booking: muzeum@orfuimalmok.hu

+3620/319 65 86